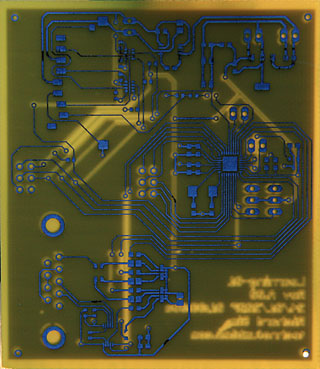

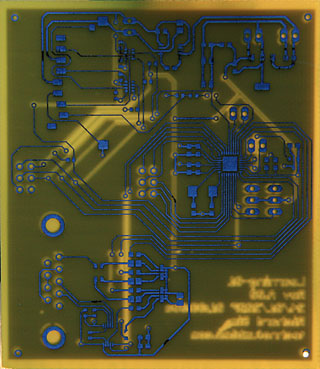

The PCBs have arrived!

After 6 weeks, the PCBs I ordered from BatchPCB have arrived - which was disappointingly slow even for BatchPCB. Their site gives a "worst-case" (US) delivery time of 18 days I believe, however the boards weren't even posted until 21 days, and took that long again to arrive in my mailbox here in Canada. I expected an additional 1-1.5 weeks on top of the US delivery time as Canada Post is pretty terrible, but 3 weeks for a small envelope? Ugh.

As I mentioned in my previous post, I ordered 3 copies of the same board so I'd have room to screw up a few times without having to start over with another PCB order - and that was a good thing, as one of the three boards had several manufacturing defects. The most noticeable of the defects is a large area on the bottom layer that did not have any soldermask applied to it, and thus was coated in solder like any other pad would be. Thankfully the defect only touches a components pad that is also connected to the ground plane (where the defect is) and is at the edge of the board, so it shouldn't require scrapping the board. The other defect was solder mask over some of the pads, which required scraping off with a scalpel.

While neither of these defects are fatal for the board, they do show a severe lack of quality control. Combined with the long delivery time, I think it's probably going to be enough for me to cut my losses and choose a more local PCB manufacturer next time, or at the very least try somewhere else. BatchPCB is cheaper (well, no actually it isn't), but no where near cheap enough to put up with such low quality. Depending on how cheap I'm feeling at the time, and how likely the PCB is to be working, I think I'll either go for AP Circuits as they're in Alberta, the next province over (

http://www.apcircuits.com), or OurPCB, which is another Chinese PCB manufacturer with awesome capabilities for their prototype PCBs, like 5mil traces/space (

http://www.ourpcb.com).

The next step is to order some parts that I'm missing from DigiKey, as I'd been putting it off until the boards arrived. Not that I meant to do that - I simply forgot to place the order. Of course, now a few of the parts that I need are out of stock for a few more weeks. :( I might place the order anyway and include some nearly-equivalent parts to use in the mean time, and then place another order when the correct parts are back in stock and rework the board when those arrive.

PCB Manufacturing

Up until now I have been making my PCBs at home (which you can read about in my previous posts), with varying levels of success. The issues mainly arose due to my heavy use of tiny surface-mount devices (SMDs), and obsession with using the smallest board possible for a design. Whenever I'm laying out a SMD board, I can't help but think that doing so requires the designer to be at least somewhat obsessive/compulsive due to the high level of concentration required for extended periods of time. If you can shut out the rest of the world and get lost in the process, it's easy.

Anyway, I can't see myself going away from the tiny-SMDs, tiny-PCBs mentality as anything else feels like I've let myself down whether due to being a waste of material/space/effort or for whatever other reason. This leaves me with two issues that have been causing me a lot of grief in my projects - transferring a design with 0.2mm (slightly less than 8mils, or 8/1000") traces and trace spacing onto PCBs, and soldering components with equally tiny pins/pads without any soldermask on the PCBs. The first issue hasn't been all that bad to deal with as it just takes more time and effort to get a good transfer, but the second issue has caused far too many boards to be scrapped. The worst part is that they get scrapped after I've already invested hours in them through the artwork transfer, etching, drilling, inserting vias, and soldering components.

That brings me to the subject of this post - I've finally decided to give a commercial PCB manufacturer a go with my latest (and greatest, of course) board. I don't want to give anything away of the designs purpose yet, so I'll just discuss its components in a non-specific way for now.

- The board consists of:

- 44 pad QFN (7x7mm)

- 36 pad QFN (10x10mm)

- 28 pad QFN (8x8mm)

- 28 pad QFN (5x5mm)

- 8 other smaller SMD ICs (most with no leads)

- Around 40-45 0402 capacitors

- Around 30 0402 resistors

- Around 10 0603 and 0805 capacitors

- A few dozen miscellaneous SMDs like ICs, connectors, etc

- The PCB is 85x60mm, double sided

For a nice picture of the sizes of some of these components, check out Curious Inventors guide to

Surface Mount Soldering. That little speck near the tip of his little finger is an 0402 component - and I have 70-80 of those to solder!

I decided to do a bit of shopping around as this was going to be my first attempt at having a PCB commercially manufactured - not so much to find the best price, but to find one that I had a way to verify that my design was acceptable and not be rejected in a few days time. This lead me to try two services,

Advanced Circuits thanks to their

Free DFM site, and

BatchPCB (SparkFun Electronics) also thanks to their DFM bot.

Advanced Circuits

I was quite impressed by the quality of Advanced Circuits FreeDFM.com service since it handled my board in my first go at running it through the verifier, and the errors (on my PCB) it provided me with were understandable and gave me everything I needed to fix them. I'm not sure if I did something wrong, but I just couldn't seem to get a good price from FreeDFMs automatic quote for my design unfortunately, so I was scared off by the prospect of paying a couple hundred dollars for a few boards of a design that I have no way of knowing would work. I'll look at them again should I need to produce at least 10 boards, but it'll simply not be worth it otherwise.

BatchPCB

BatchPCBs verifier script is unfortunately more crude than Advanced Circuits, and many times it returned PHP errors while trying to just upload my design. Once that was taken care of, I was confronted with a lovely error of "aperture 36 too small: 0.0056" (or similar). Now seriously, what are they thinking? You don't know what aperture 36 is - it's something the PCB program makes up for submitting the files to the PCB manufacturer. The only way you can know what it's talking about is to manually open the files, find a line similar to "%ADD36C,0.0056*%", change the size to something huge so it's recognisable on the board, view it in a program like ViewMate, and narrow down the problem from there. This particular error turned out to be due to a library part I was using being designed with rounded SMD pads (rather than the standard square pads) - modifying the library to use square pads fixed the problem right up.

After that was out of the way, BatchPCB did provide me with an additional error that FreeDFM did not tell me about, but I think that may have been due to FreeDFM having slightly less restrictive requirements for board layout. The final price from BatchPCB? $20 per board + $16 shipping (I ordered 3 boards, so I have a few spare just in case).

So there we go, it did take nearly a day of fiddling and Googling, but I have my first PCB order under way. As BatchPCB works as an aggregator for a Chinese PCB manufacturer, I'm not expecting to see the boards for another month due to shipping times - but maybe I'll get a pleasant surprise.

Labels: dfm, electronics, pcb

Updates on recent posts

It's been a few weeks since my last post, but rest assured that I've been quite busy working on more projects!

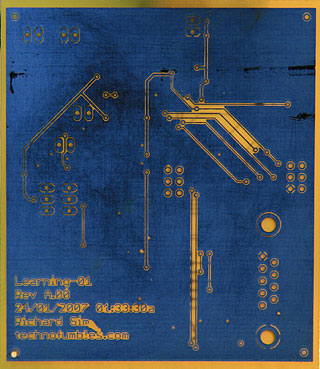

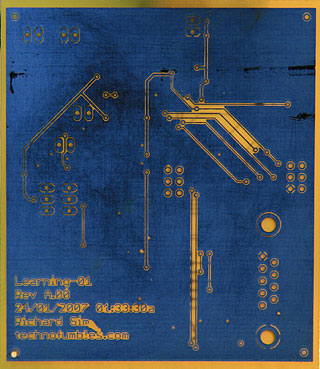

Homemade PCB

The home-made PCB in the previous post turned into a bit of a disaster when I tried to take the toner off the traces with a Scotch-Brite pad. It turns out that brute force and abrasive materials aren't the best way to remove toner from 0.2mm traces. Who'd have thought? ;) So I've etched the board again, and took the opportunity to revise the design slightly while I was at it, and this time tried acetone (well, nail-polish remover) to remove the toner. Acetone works much, much better than Scotch-Brite pads.

- In the new revision of the board, I made the following changes:

- VIAs have a larger diameter for the pad-area as my drilling wasn't terribly accurate and I destroyed many VIAs on the original board.

- Clearance around many VIAs was improved to reduce the risk of solder bridges.

- Minor component positioning changes to shorten and simplify routing of traces.

- Added my name and URL to the top layer (it was already on the bottom layer).

Now all I have to do is get it soldered without any short circuits, and that's proving to be a big challenge!

V7 Navigation 1000 Menu Button

Shortly after posting the 'M' button fix with the steps required if you'd done the USB-port hack in another of my posts, I realized that it was entirely unnecessary to do any hardware modifications to fix the bug - rather you could do it all with just Explorer and a little back-and-forth with the SD card between your GPS and PC.

Anyway, life kept me from posting an update to that, but thankfully someone else has saved me the time! If you head on over to the always-awesome

instructables.com, you will find a nice article by dadefatsax which explains all the necessary steps.

Unlock V7 Navigation 1000 GPS.

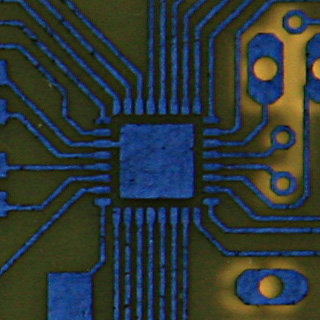

First homemade toner-transfer PCB

A coworker has been raving for a few weeks about how easy and quick it is to make PCBs (printed circuit boards) at home using what is commonly called the "toner transfer" method. Given that the only other way I've used to make PCBs at home (using photo-resist coated boards and a UV exposure box) had pretty terrible results and that I wasn't too eager to drop money on an untested circuit design to get it commercially made for me, it seemed worth the effort to have a go for myself.

Tom Gootee describes the method in incredible detail (if a little disorganized) on his website,

Easy PCB Fabrication. I also bought a laser printer for this purpose (well, I wanted a laser printer, and this was a good excuse...) - I decided to go for a Brother HL-5250DN as it has 1200x1200 DPI resolution as I didn't feel that a 600x600 DPI printer would be able to reproduce the SMD pads and fine traces that I would be using (0.2mm! That's less than 8mils for those of the non-metric persuasion, or about 4 'dots' at 600 DPI). I didn't diverge very far from Tom's instructions as this was my first attempt (ok, second - the first failed to transfer the toner completely to the PCB) with the exception of spending quite a bit more time ironing the design to make sure that the toner transfered this time.

I also picked up an etching kit, heater, and supplies from a local electronics store. Originally I was a bit annoyed when I opened the box to find a regular Tupperware container, an aquarium pump, and a piece of plastic to (poorly) hold the PCB while it etches - however I probably couldn't have picked up the items individually for too much cheaper anyway, so it wasn't so bad. I was hoping that the kit would contain a nice tank with graduations marked for the volume of etchant or at least depth though. Instead, the 'tank' was quite large - far larger in fact than I'll ever need - which also means that it requires a lot of etchant to fill it enough to cover even a small PCB. As I did not know this at the time, I picked up only a single 500ml bottle of Ferric Chloride (a common etchant) and as a result had to dilute it 1 part FC to 3 parts water in order to get it to just over the height of my PCB.

At this point I was having serious doubts that I'd see any success as I hadn't seen anything in any of the PCB making tutorials online about diluting FC. As it turns out, there was no problem other than it taking longer to etch, about 20 minutes I believe (but I wasn't looking at the clock). I'm sure that the heater and pump helped greatly with this, and without them I probably wouldn't have seen any results for a much longer period.

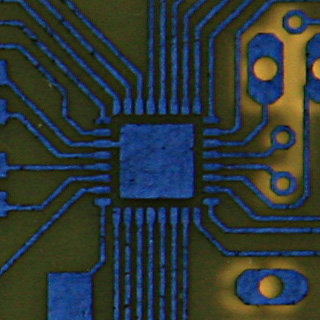

So what were the results like for my crazy-tiny traces and SMD pads? Outstanding! Considering 0.2mm is the minimum size for many commercial PCB manufacturers, and even below the minimum for some, I'm very surprised by how well even the tightest areas of the PCB turned out. To the left you can see a closeup of a MLF32 footprint IC with 0.2mm traces and spaces.

The bottom layer of the PCB has a few quite large holes in it, but I think that was mainly due to the fact that I didn't spend much time ironing that side during the toner-transfer step as it didn't have many fine traces on it. The holes didn't break any traces, so that's fine.

Labels: electronics, homemade, pcb, printed circuit board, smd, surface mount, toner, toner-transfer

V7 Navigation 1000 Menu-button bug fix

Those who have a V7 Navigation 1000 have probably noticed that the Menu (M) button doesn't actually go to the menu. It doesn't do much of anything actually (other than behave as "up" for a few menus), which is quite disappointing since there are only really 3 buttons you can use on the front (excluding the backlight on/off button) and the other two you will usually want to keep at their default functionality (zooming in and out).

Oh hey, what do you know - if you followed the instructions in my last blog entry, you will have access to change this!

- Plug the V7 Navigation 1000 into a USB port on your computer and turn it on.

- Browse to \Flash Disk\MyGuide\ in Explorer (on the PC, not the GPS).

- Copy the 1.3mb Data.zip to your PC's hard drive.

- Rename the Data.zip on the GPS to Data.orig (as a backup).

- Open the Data.zip that you copied to your PC and extract config\keybind.txt from the archive.

- Open keybind.txt in Notepad and scroll down to the [CARPOINTA1000] section.

- Below this, add the following line: UP="ROUTEINFO". The section will now look like this:

[CARPOINTA1000]

UP="ROUTEINFO"

39="ZOOMIN_DISCRETE"

37="ZOOMOUT_DISCRETE"

- Save keybind.txt and replace the original keybind.txt in Data.zip with your edited keybind.txt. Make sure that you actually replace the file and that it goes into the correct directory of Data.zip.

- Copy the updated Data.zip back to the GPS (put it back in \Flash Disk\MyGuide\).

Done and done! You can now start MyGuide and the Menu (M) button will now behave just like going to Route > Info.

You can actually replace

ROUTEINFO with many other useful commands, of which

MAINMENU is a good choice (as it is obviously the intended behavior of the Menu button, but I found

ROUTEINFO to be more useful personally). Have a look through

keybind.txt to get an idea of what other commands you can try.

Of course, if you don't use the zoom in/out buttons, you can change the bindings on those too.

Labels: bug fix, bugs, electronics, GPS, hacking, hardware, iGo, MioMap, MyGuide, PNA, software, V7

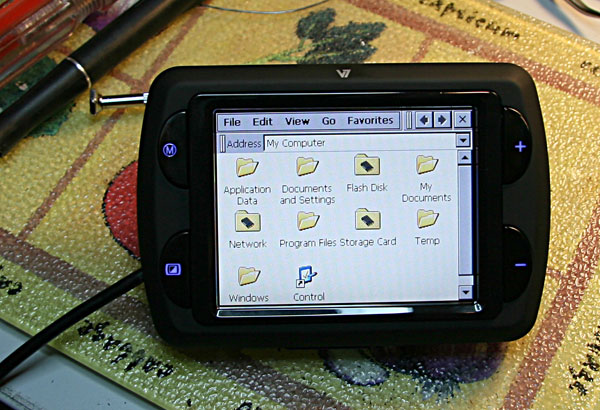

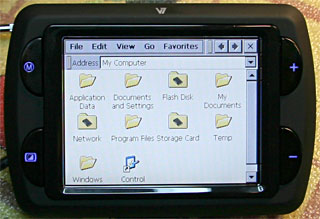

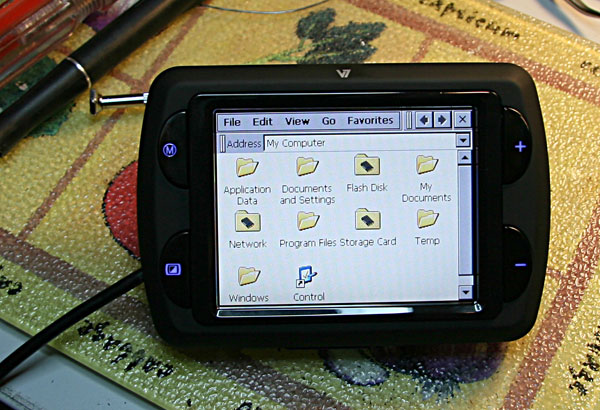

Hacking the V7 Navigation 1000 GPS

On Boxing Day I picked up a cool new toy - a V7 Navigation 1000. It's an in-car GPS unit with quite nice hardware and software (albeit perhaps matched up and configured by monkeys, and somewhat buggy too). As with any new electronics gadget, I set out looking for updates as soon as I had my hands on it - which lead me down the road of hacks for similar GPS units. It turns out that the software the V7 unit runs,

MyGuide, is just

iGo re-branded and is exactly the same as what many other common GPS units run under various names such as

MioMap.

While it's great that the Navigation 1000 has all its maps on an included 1gb SD card, this lead to the problem that they did not include any way to access the rest of the files on the device (such as the configuration files for MyGuide). Devices like the Mio DigiWalker C310S have a USB port since their maps are stored on internal Flash memory and not an SD card, and this let their owners do some simple software hacks to get full access to reconfigure the GPS software as well as directly use Windows CE. Yes, these babies run on Windows CE!

Knowing that there was Windows CE under the hood, and that there was a quite powerful processor powering the device (400MHz ARM), this lead me to assume that there must be a USB port hidden somewhere inside - perhaps behind what looked like covered up ports? After all, if I was developing a Windows CE device, I'd want a USB port for development and debugging!

And so it began...

As with all hardware hacks, please do not attempt this unless you are experienced in electronics and soldering, and have all the necessary equipment. You'll want a good soldering iron with a very fine tip (made for SMD work, not through-hole!) - not the kind you get at RadioShack.

First, start by taking off the front case. There are 4 small phillips screws on the back of the V7 Navigation 1000 that you'll have to remove. None of my phillips jewelers screwdrivers were small enough to fit into the screw hole, so I used one of my medium-sized flat-head jewelers screwdrivers - it worked fine. As with most gadgets, the case is also sealed by plastic clips around the edge. After several attempts with my trusty jewelers screwdriver that had just saved me, I gave up and used my thumb nail. In no time I had the case open. Woohoo!

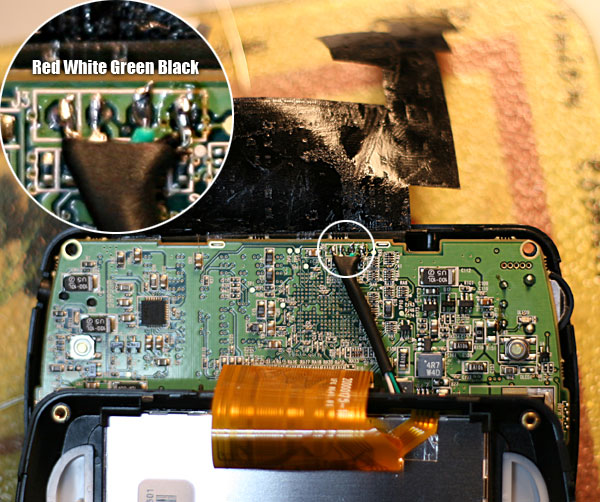

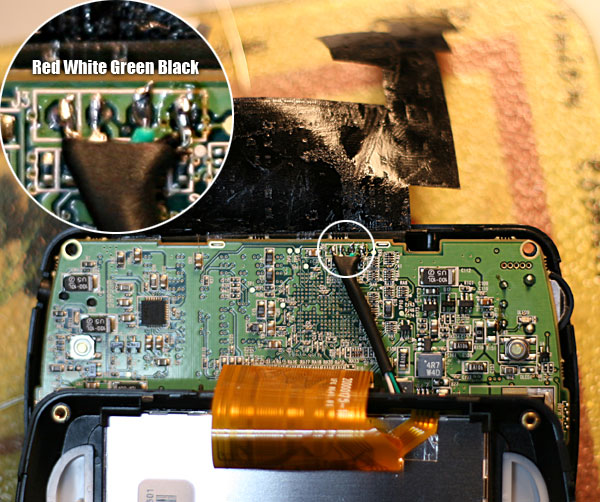

With the case open, the first thing you'll see is most of the PCB is covered in shielding tape (which is very sticky!). I'll tell you now - all the interesting components are inside a metal shield on the back of the PCB, and it's soldered down pretty damn well. After I came to that realization, I almost packed in the towel as I assumed that any way to access USB would also be hidden in there. While I did some last minute poking around the PCB, I saw 4 test points marked J3. Test points marked as a jumper? Very odd... and being that USB uses 4 wires (+, -, D+, D-), I had a "eureka!" moment.

Where will you find these golden test points (no, seriously - they are gold plated)? At the very top of the front of the PCB, nearly in the centre (above a whole lot of VIAs as it would seem that the ARM chip is in a BGA package). To get to them you will have to remove the shielding tape from the top of the PCB - it's easy enough as it's only stuck to the top of a few components, so just take it slow and be careful.

If you look closely at J3, you will see that of the 4 test points, the left-most test point is separated from the other 3. This is VCC (V+). Looking closely at the right-most test point, you can see that it is connected to the ground plane. This is GND (V-). As for the other 2, I had no idea other than the standard order is V+, D-, D+. GND. As V+ and GND were in the correct order, I went with the assumption that D- and D+ were too. I was right. At least some people follow standards! :)

We now have a way to connect to this device by USB, all we need now is to connect it up. I had the choice of soldering a USB cable directly to the PCB or putting a mini-USB connector in the unit and being able to plug a standard mini-USB cable in, and would definitely have gone with the later if I wasn't in a rush to see if all my assumptions about the USB pinout was correct (or if it even was a USB port). As such, I found a spare mini-USB cable, cut off the mini-USB plug, and stripped the 4 wires. If your USB cable has shielding (it should), just cut that back also. You'll want about 10cm of the USB cables shielding stripped back, as it's too fat to route through the GPS unit. Next, strip the ends of the 4 wires in the cable. You only want to have 1-2mm (that's a bit less than 0.05-0.1") of bare wire at the ends, as the actual test points that you'll be soldering them to are about 1mm in diameter each and any extra bare wire could easily make contact with other wires or components causing all kinds of grief (and likely a dead GPS and perhaps PC too if it's connected at the time).

You can see that I've soldered them in the order (left-to-right) Red, White, Green, Black. These are the standard colours for VCC, D-, D+, and GND respectively in USB cables, and as such they should be the same in any USB cable that you cut up for this hack. If they are not, or if you just want to be extra careful (I was!), you can always use a continuity tester on the mini-USB connector that you cut off from the end of the cable (

pinout).

You should also note the use of heat-shrink tubing (and further on the use of electrical tape) to prevent any of the USB wires (and shielding of the USB cable itself!) coming into contact with the PCB or components where they shouldn't.

Next up we need to make a hole to feed the USB cable out from. I chose to make use of the area above the power button as it looked like it was originally designed to have a port there (the PCB even had room for an unknown connector - but it wasn't USB). You can make it anywhere on the case obviously, another good location would be the top next to the stylus as that would minimize the internal-routing of the USB cable (given the amount of shielding the GPS unit has, this would likely be a good thing). Dremel time!

When routing the USB wires, be careful to avoid blocking the front-panel buttons and their backlight LEDs. I found it was quicker to just turn the unit on than to look around the PCB for the 4 LEDs. When that's done, you should have something looking like this.

Snap the case back on and put the 4 screws back in, and you're done! You might want to turn it on now to make sure that it still works...

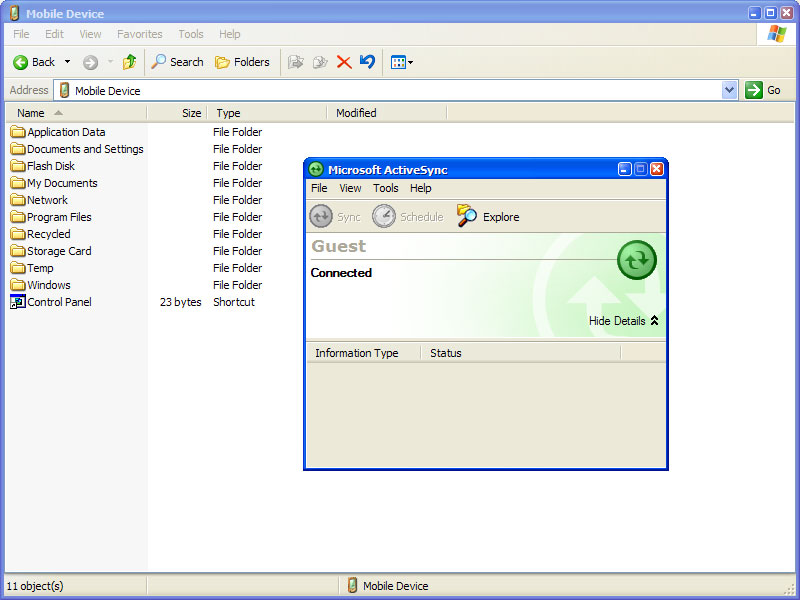

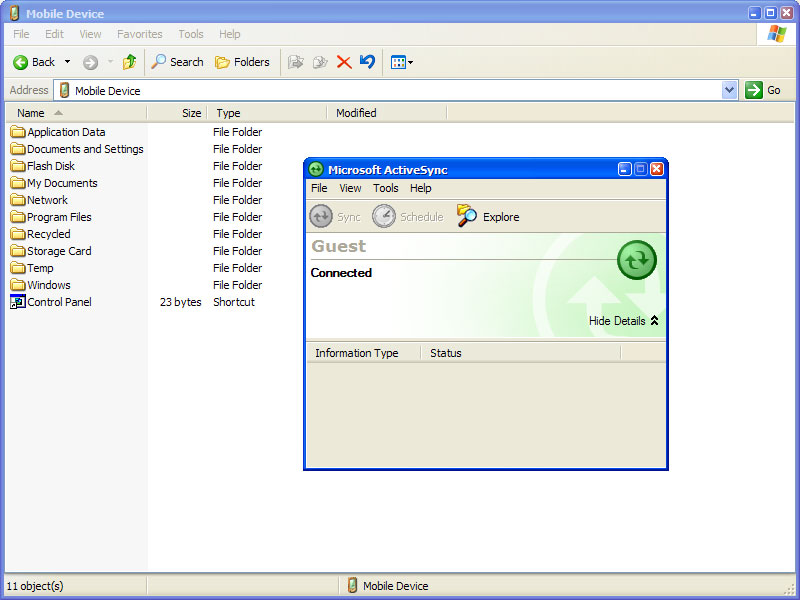

Download and install Microsoft ActiveSync (

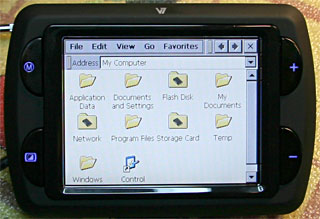

here) as this will let you access the device just like it was a PDA. Plug the GPS unit into one of your computer's USB ports, and you should be good to go! If you click 'Explore' in ActiveSync, Explorer will open to allow you to browse around the file system. The first thing you should do is back everything up, though there are some files that you cannot (system files).

One easy hack you can make right off the bat with MyGuide is to add a button from the startup screen to run Explorer on your device. To do this, copy

\Flash Disk\IGOPATH.TXT to your PC and create a backup copy of it also. Rename the file on the device to

IGOPATH.bak. Back on your PC, open

IGOPATH.TXT in Notepad and add the following line to the end of the

[Multimedia] section (so this should be the last line in the file):

Explorer= "icons/files.bmp", "\\Windows\\Explorer.exe"

The file should now look like this:

[pre_init]

LangSyncOn = "\\flash disk\\langsync.exe"

[pre_quit]

LangSyncOff = "\\flash disk\\langsync.exe"

[modules]

Settings = "icons/settings.bmp", "settings", 1

Multimedia = "icons/media.bmp", "Multimedia", 0

[Multimedia]

Picture= "", "\\Flash DIsk\\XImage\\XImage.exe"

Movie= "", "\\Flash DIsk\\XMovie\\XMovie.exe"

Music= "", "\\Flash DIsk\\XMp3\\XMp3.exe"

Explorer= "icons/files.bmp", "\\Windows\\Explorer.exe"

You can now copy this file back to the V7 Navigation 1000 (under

\Flash Disk\, of course), then power-cycle the device so it gets the new configuration. If you click on Multimedia on the first screen now, it will list Music, Movie, Picture, and... Explorer! Tap on Explorer, and there you have it - Windows CE Explorer is running on your V7 Navigation 1000.

From here you can go ahead and install lots of normal Windows CE software such as games, and utilities, or just mess around with MyGuides configuration (custom skins, hidden features, and more are all possible... maybe even bug fixes). Since the Mio uses the same software, a lot of its hacks should be portable to the V7.

The

GpsPasSion forums are a great source of information on Mio hacking, so should be one of your first stops.

Happy hacking, and if you find something cool, drop me a note!

Labels: electronics, GPS, hacking, hardware, iGo, MioMap, MyGuide, PNA, V7

Application Note: High-Speed DSP Systems Design

spru889.pdf (pdf file)This PDF from TI is a very interesting and easy to follow guide to designing high-speed systems (not specifically DSPs, but anything ~10-20MHz and up). I came across it while trying to fill in the blank spots that Digital Electronics Guidebook (reviewed previously) left with regards to the termination of buses, and found just about everything I could hope for with regards to designing a solid, reliable high-speed system.

- The application note is divided into 7 main sections:

- Challenges of High-Speed DSP Design

- Transmission Line (TL) Effects

- Crosstalk

- DSP Power Supply Design

- Printed Circuit Board or PCB Layout

- Phase-locked Loop (PLL)

- Electromagnetic Interference

What really suprised me about the AN is just how easily digestible the information was, despite a lot of it being at the limits of my current understanding of electronics. A great example of both the knowledge and understandability is the section on determining decoupling capacitor values, where both "rules of thumb" and fully worked-through equations are given for the values.

Review: Digital Electronics Guidebook

Amazon.com: Digital Electronics Guidebook: With Projects!: Books: Michael Predko

Amazon.com: Digital Electronics Guidebook: With Projects!: Books: Michael PredkoWhile this book is not very well known and doesn't sound particularly intellectual, I've found it to be a hidden gem - albeit with many sharp corners to cut yourself on if you're not paying attention. The sharp corners have proved to be both a curse and a blessing in disguise, as I frequently found myself scratching my head as to what was really meant by something that was clearly an error, and as such had to work through the logic myself to see what was going on and what the correct information was. This was unfortunately so frequent that I soon found myself double checking everything in the book as I had little faith in the correctness of even simple things.

Of these simple errors, the single most disgusting and frequent on is his use of 0.1uF tantalum capacitors for decoupling throughout the entire book. When decoupling was initially discussed, he stated that he uses tantalum capacitors because they are better than ceramics for this purpose (due to their lower ESR; effective series resistance) - and this is completely wrong! Looking at any datasheets, or doing research on this topic online or in any other book will show you that you actually should avoid using tantalum capacitors for this task as they are nearly useless. Given frequent the need for decoupling digital circuits, this error can be seen in every single circuit in the book.

Myke Predko gives a very in-depth treatment to the operation of TTL gates with a somewhat less in-depth treatment of CMOS gates. This is rather suprising considering that it is stated several times throughout the book that CMOS gates are far more prevelant in modern circuits and microcontrollers. Having said that, CMOS gates are not ignored and there is a decent amount of information about them scattered through the book.

That brings me to the next point; the books layout is quite scattered in several parts. A good example of this is the several parts of the book dedicated to the operation of buses, where initially several pages were dedicated to their introduction only for it to be interrupted by a completely different section without all the questions that were raised having been answered first. Later on they are picked up again and discussed in some more detail - and dropped again, still before all your questions have been answered! The cycle then repeats with more discussions later.

More disturbing than this is the important questions that were raised that simply were swept under the carpet without any attempt at even giving you a direction to look into yourself. An example of this from on of the first discussions on buses is the termination of long buses to avoid reflections when the signals reach the end of the lines and are not fully attenuated yet. The issue is brought up and a clear description of the problem is given.. but nothing on what to do to solve it! In a much later discussion on other aspects of buses (specifically communication), it is briefly mentioned that you can put a resistor of "a few hundred k" at the end of the bus line and ground to reduce the issue. That's nice. Does it apply to all bus designs? Only this one? Should it always be "a few hundred k"? From the initial discussion of this subject, this is a very important issue and can easily be fatal to a circuits design, so where's the solution?

As I stated at the very beginning of this review, I found this book to be a hidden gem. Given everything negative that I've said about the book so far, how can this be? Well, despite the abundant typos, errors, and mislabeled diagrams, the writing is very, very easy to understand and goes a lot slower and more in-depth than most similar books. Coupled with the need to double check most things for yourself, you get a very good understanding of the operation of the devices and circuits that Myke discusses - and as such, this has been one of the few books that I've read recently that I feel that I've truely asorbed and processed the information in.

Now for the bad news.

You're unlikely to find this book any longer as it is now out of print (it was in print for less than 4 years it seems from the publication date given on Amazon). There are some alternate sellers, who still have the book available, listed on the Amazon page for this book, so hope is not lost.

Overall I'd give the book 4/5 stars, which is a testament to how good the book is to recover from its many serious flaws.